Precision machining and manufacturing

We have the most advanced 5axis, 4axis, and 3axis CNC machining technology and processes, which can be used for rapid prototyping and mass production.

- Precision machining of over 200 types of metals and plastics, and over 60 types of surface treatments.

- Understand the manufacturing needs of parts and provide real-time quotes.

- Professional service team, fluent in English for business communication.

The services we can provide for you

From concept to design, prototype production, and mass production, always ready to turn your ideas into reality and provide advanced product manufacturing solutions.

We have the latest rapid prototyping technology to meet your design challenges and will work with you to validate and improve your product ideas, functional testing, and engineering validation.

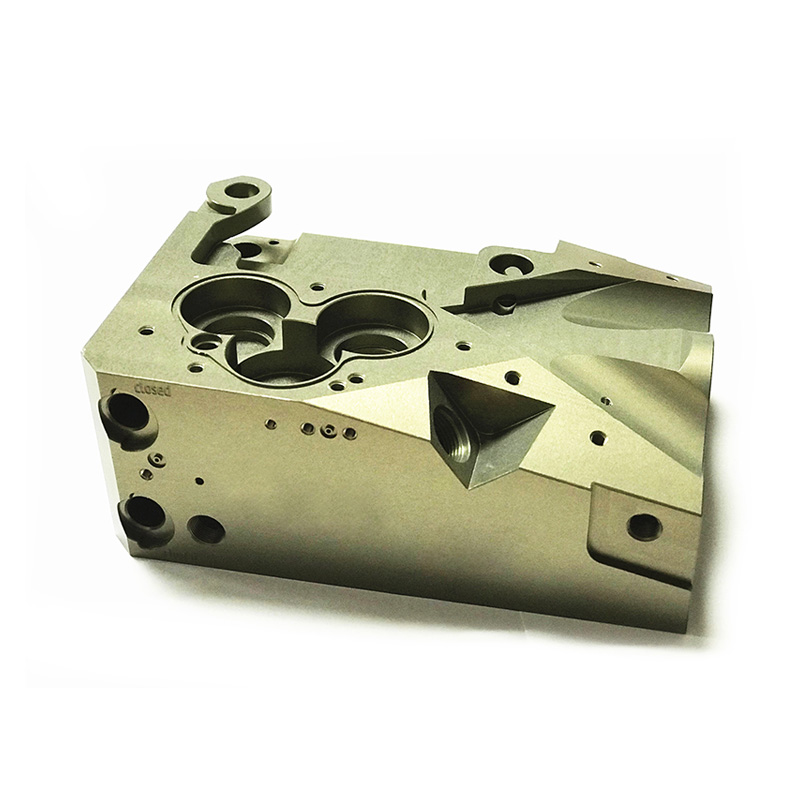

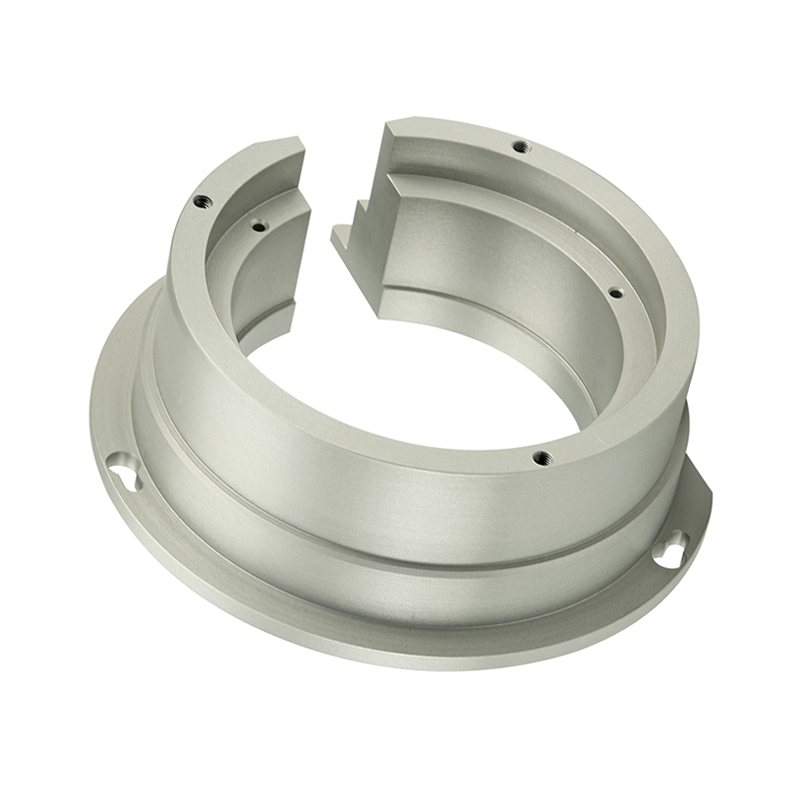

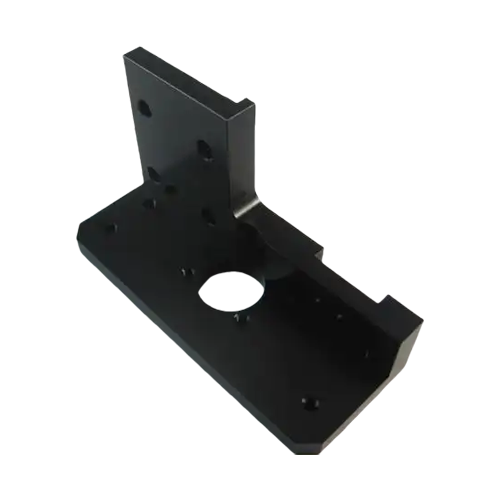

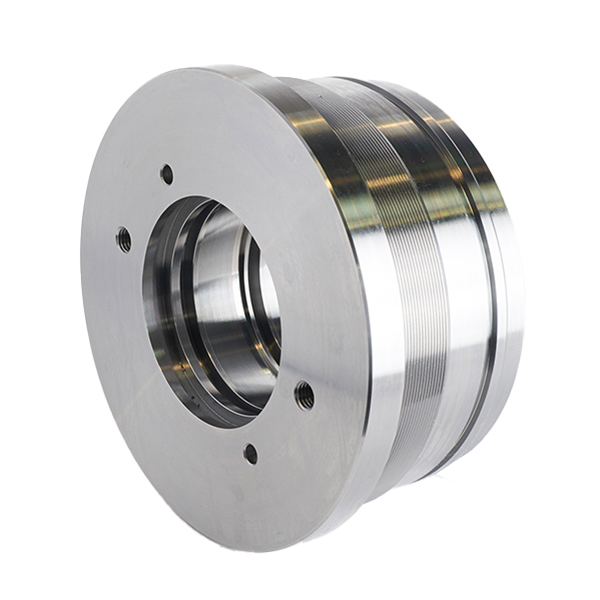

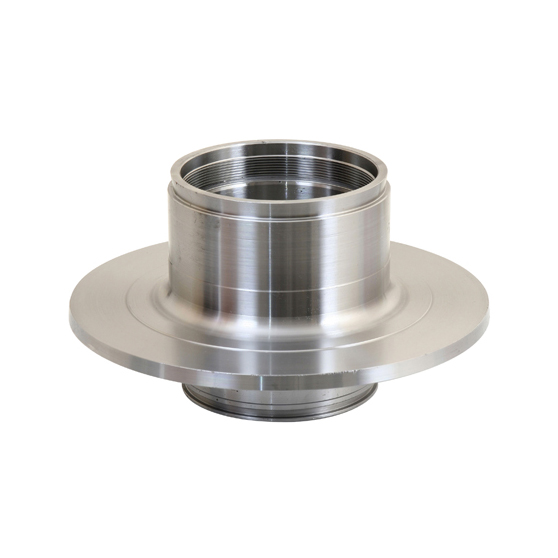

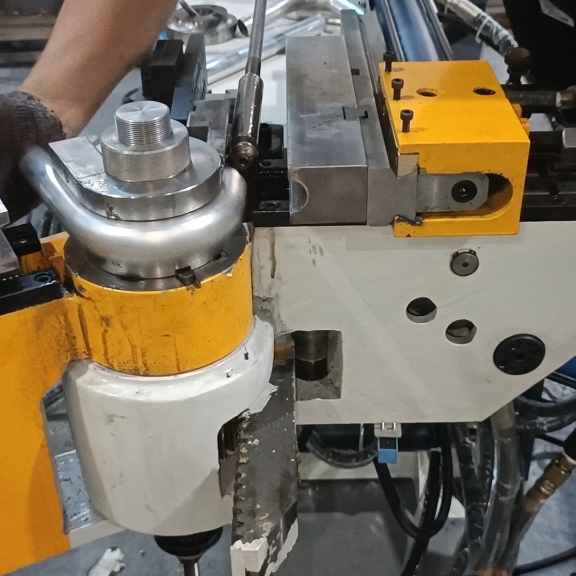

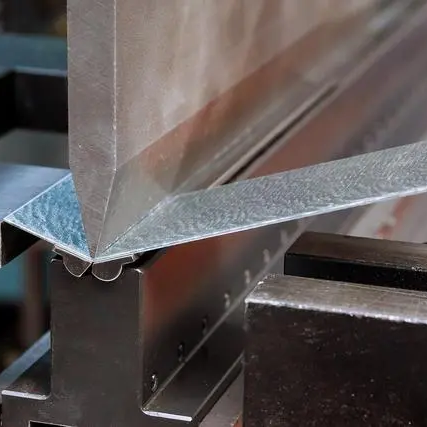

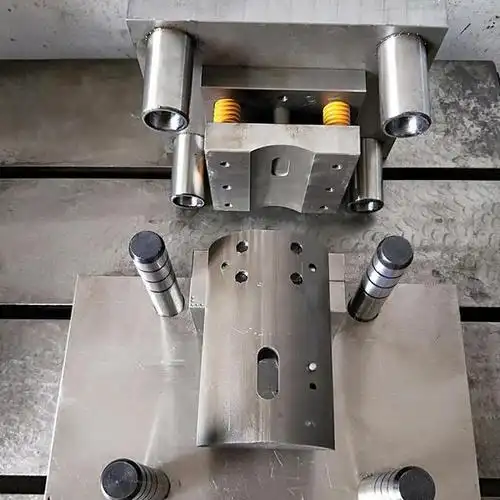

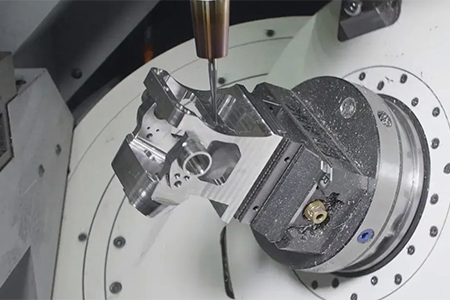

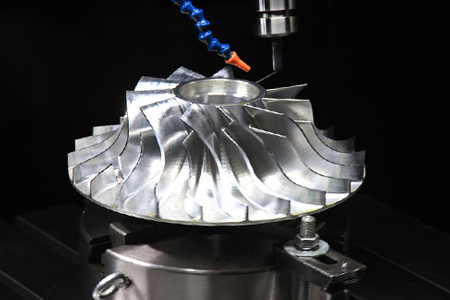

We offer 3 4 5 axis precision machining of complex geometrics-including CNC milling and CNC turning of various materials, as well as drilling, tapping, EDM, and wire cutting.

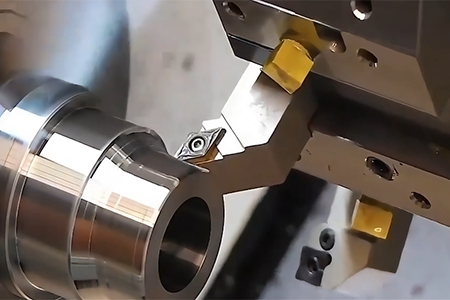

Produce complex and precision sized custom parts to specific specifications and needs, providing high quality metal or plastic CNC turning parts for rapid prototyping or small series production.

Custom CNC milling for plastic and metal parts to meet a wide range of CNC machining tolerances to meet your specific design and surface finish requirements.

A range of customized solutions for consulting, part design advice, production planning, CAD creation, sheet metal part machining, surface finishing and assembly services.

24-hour sample express channel (first sample delivered within 72 hours), full process delivery of small batch orders within 10 days,50% faster than the industry average.

Start your prototyping and manufacturing production with us in just four easy steps

01

Directly upload your file or send your project message through the quote page. All files are under NDA supported.

02

Within 12 hours, we’ll send back the Design For Manufacture analysis and real-time quote.

03

Once the order is confirmed, we’ll start the manufacturing process with your CAD design.

04

Prototypes and parts will be produced within a few days and delivered directly to you by international express.

Why Choose Us

Background advantage

Sumitech is a subsidiary of UNIMECH Group, with strong financial support and foreign advanced technology support.

Sumitech set up offices in Malaysia and Hong Kong.

Equipment advantage

Sumitech purchased high-end imported production equipment: Germany DMG 5-axis machining center, Germany DMG 3-axis machining center, USA Haas 5-axis machining center, USA Hass 3-axis machining center, Japan OKUMA CNC lathe,etc.

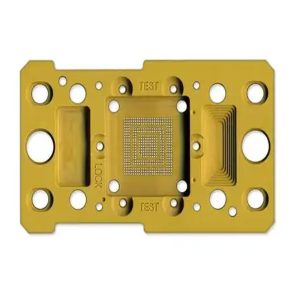

Quality advantage

Sumitech purchased high-end imported measuring equipment: Germany ZEISS CMM, Switzerland TESA height gauge, Japan Hitachi Spectrogram, Japan Mitutoyo coating tester, HRC hardness tester, surface finish tester, roughness tester, etc.

At the same time, Sumitech has a complete quality control system, including ISO9001 and medical industry ISO 13485.

Processing advantage

Sumitech has high-end five-axis machines, so it is our advantage to process special-shaped, complex, strict tolerances and parts that require five-axis linkage. At the same time, our CMM equipment and spectrometers can provide customers with accurate dimensional inspection reports and material analysis reports. In combination, we are able to provide our customers with traceability quality control from raw materials to finished products.

Industry advantage

Sumitech has medical ISO13485 certification, which can provide customers in the medical industry with quality assurance and traceable quality control management process.

Sumitech has a number of global leading semiconductor industry customers, such as KLA, ASM, etc.Due to long-term service to semiconductor industry customers, we have accumulated valuable processing experience in this industry.

Material advantage

Sumitech has many years of processing experience in titanium alloy materials (TC4/TC5/TC7, etc.), which can easily solve the problem of difficult processing of titanium alloy materials.

Sumitech has many years of processing experience in kovar alloy, Invar alloy, which can easily solve the problem of difficult processing of titanium alloy materials.

Industry experience

Production scale

Professional team

Precision production equipment

High end testing equipment

Online service

The customer's word is more important than ours

What do satisfied customers say about how we meet their requirements

Your thoughts are important to us

The same goes for quality

That’s where we at come in. We’re a China-based rapid manufacturing company with Western roots and a North American division in Missouri. All of our products stand up to strict Western critical tolerance criteria, making us a leader in the production of rapid prototypes and low-volume manufacturing. Our customers include leading European and North American companies like BMW, FLIR Systems, and Beckman Coulter.

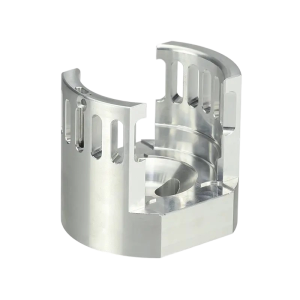

Product Display

Be good at precision machining,mass production.

Put your parts

into production today

All information and uploads are secure and confidential.

From rapid prototyping to production

Whether you need a few parts or more than 10,000 units as end-use production parts, CNC machining is the ideal manufacturing process. We offer custom CNC services

Rapid prototyping

- Instant quote

- Instant DFM anti-aunt

- Good quality

- Fast delivery

Small batch production

- Cost flexibility

- Production grade quality

- Quick delivery

- Test the market before you invest

On-demand production

- DFM optimization engineer with experience in Foncet

Latest Post & Article

The key technology system for achieving nanoscale precision in semiconductor

一、 Precision machining process control 1. Optimization of cutting parameters

1、 Technical equipment advantages: Intelligent CNC cluster: equipped with 20

一、 Industry positioning and technological strength 1. Precision manufacturing benchmark

Provide demand

We can achieve your idea