Precision 4 axis CNC machining service

Numerical control machining technology applied in fields such as aerospace, automotive manufacturing, medical equipment, and electronic products.

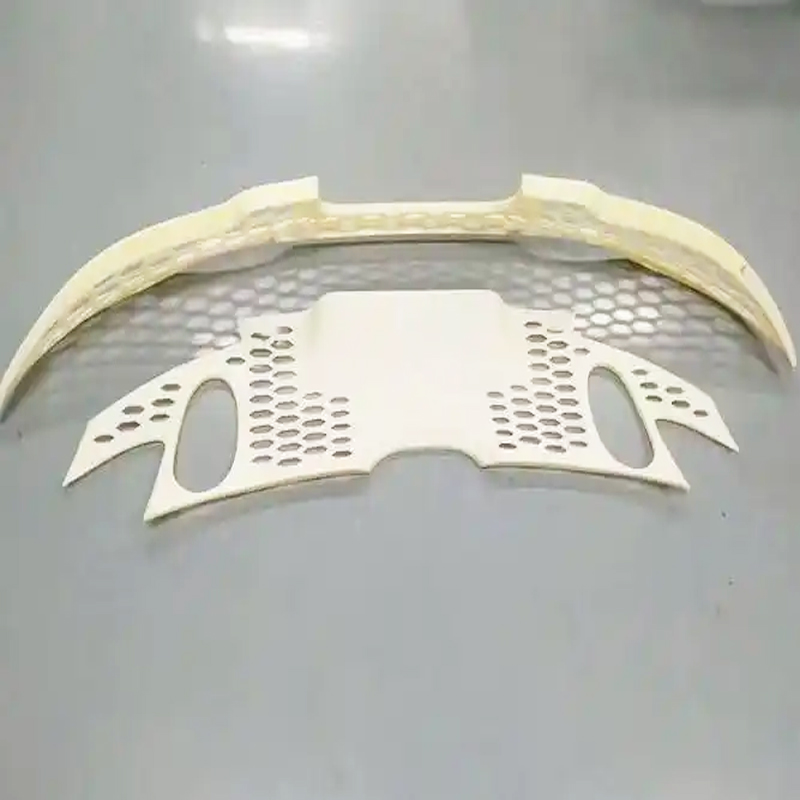

Product Display

Various materials and shapes all can customized machining

Sumitech Factory 4 Axis Machining Advantages

1. Technical capabilities and equipment advantages

Complex geometric processing capability for polyhedral processing: Multi angle positioning of the workpiece is achieved through the fourth rotation axis (A-axis/B-axis), and four sided processing (such as box body, flange, gearbox, etc.) can be completed without repeated clamping.

Surface machining: supports continuous machining of cylindrical and spiral parts (such as camshafts and impeller bases), with surface accuracy up to Ra 1.6 μm.

High precision and stability, using a high rigidity four axis turntable (repeated positioning accuracy ≤ ± 5 arcseconds) to ensure synchronization accuracy between the rotating axis and the main spindle.

Vibration reduction design, optimized fixture and tool path planning, to avoid resonance errors in high-speed cutting.

2. Efficiency and cost advantages

Reduce clamping frequency

Single clamping with multiple processes: For example, when processing the differential housing of a car, the side hole system, end groove, and thread processing can be completed in one go, increasing efficiency by 30% -50%.

Shorten auxiliary time:

Compared with traditional three axis machining, it reduces workpiece flipping and calibration time, and compresses the overall production cycle by more than 20%.

Reduce overall costs

Labor cost savings:

Automated four axis programming (CAM software linkage) reduces manual intervention and lowers single piece processing costs by 15% -25%.

3. Industry adaptability and case studies

Automobile manufacturing: complex structural components such as engine cylinder blocks, gearbox housings, and steering knuckles.

Aerospace:

Multi angle hole machining of wing ribs and support components.

Energy equipment: efficient molding of valve bodies and pump casings.

Medical devices:

Multi sided precision machining of orthopedic implants (such as acetabular cups).

Successful case:

Processing motor housings for new energy vehicle companies, completing side heat dissipation holes and end face positioning slots through four axis linkage, with a yield rate increased from 88% to 97%.

For the processing of hydraulic valve bodies, replacing traditional 3 time clamping with four axis one time clamping reduces the delivery cycle by 40%

Application examples of 4 axis machining

1、Automotive parts processing: such as bumpers, interior parts, headlights and other plastic parts, with complex shapes and high requirements for size and surface quality. Four axis processing can complete the processing of these complex shapes in one go, improving production efficiency.

2、Aviation parts processing: Aviation parts have strict requirements for accuracy and shape, and four axis processing can meet these needs, such as using four axis adjustment fixtures for precise clamping and processing.

3、Typical parts on the production line, such as cylindrical camshafts, sleeve spiral drills, spiral columns (shafts), box type parts, cylindrical spiral gears, and flowmeter rotors, are all practical applications of four axis machining in the production line.

4、In summary, four axis machining is widely used in automotive, aviation, and general industrial production, and can meet the machining needs of high precision and complex shaped parts.

Provide demand

We can achieve your idea