Sheet metal processing

Are you looking for reliable sheet metal processing and production partners?

We can provide assistance in obtaining online quotations and free analysis of part processes within a few hours

Professional sheet metal processing service provider

The company has a team of designers and technical engineers specializing in sheet metal processing, with over ten years of experience in the sheet metal processing industry. Therefore, we provide a range of customized solutions for sheet metal production. We treat each order as a separate project, providing consultation, part design advice, production planning, CAD creation, as well as sheet metal part processing, surface finishing, and assembly services. No matter what requirements your project has, we can excel in completing them.

Customized sheet metal manufacturing services

Whether it's complex part geometries, specialized materials, extremely strict tolerances, or specialized precision machining, we can provide one piece and batch production

laser cutting

We have 2D and 3D laser cutting machines that can meet most of the market demands. High precision, high speed, and high efficiency help us provide highly competitive costs

Sheet metal bending

Sheet metal bending is the process of applying force to a metal plate to bend it at a certain angle and form the desired shape

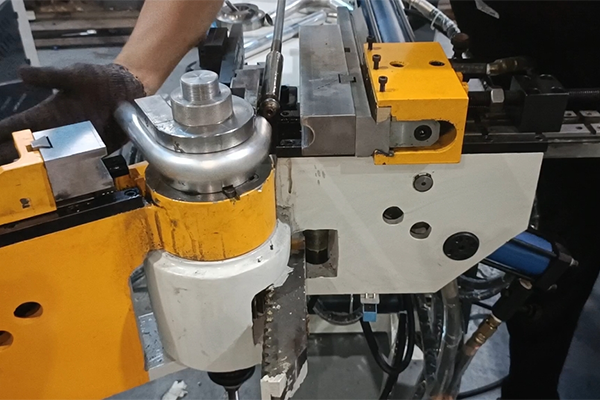

Bending and Manufacturing

Pipe bending and manufacturing involve reshaping pipes using techniques such as bending, cutting, or assembly to create specific structures or components suitable for various applications

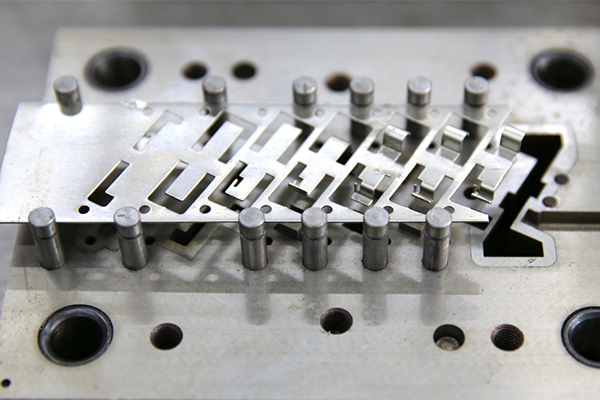

Metal Stamping

We are experts in high-speed precision metal stamping, deep drawing stamping, progressive die stamping, single die stamping, and composite die stamping.

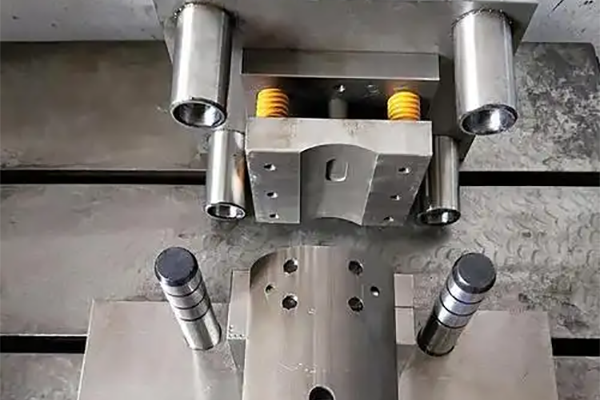

Stamping die

We provide a full range of molds, such as punching molds, bending molds, deep drawing molds, forming molds, etc

Welding and assembly

We offer MIG, TIG welding, laser welding, and robot welding for steel, stainless steel, aluminum, and copper, which enables our team to handle both simple and complex welding assembly projects

Why Work With Us?

Meet international standards

Custom metal fabricated parts have to follow industry standards. We pass certificates of ISO 9001, IATF 16949, and information security. That means our metal fabrication service conforms to the International standard strictly. We operate multiple advanced machines to meet the need for sheet metal fabrication.

Diverse combination

It is a time-consuming hassle to communicate with more than one supplier. Today’s industrial and manufacturing operations are more varied than ever. A metal fabricated company that can provide flexible and complete services is in greater need. Our diverse service combination can meet the special need of every project.

Speed

We are committed to eliminating unnecessary communication and perfecting the processing. Centered on the value of our services, we are able to complete projects efficiently with fewer errors. The process reduces our expenses and lowers the cost of metal fabrication.

Surface finishing services

Depending on your requirement, we provide you with the following surface finishing for your sheet metal parts. We have manual department to responsible for it and work great and reliably with our suppliers for more finishing services.

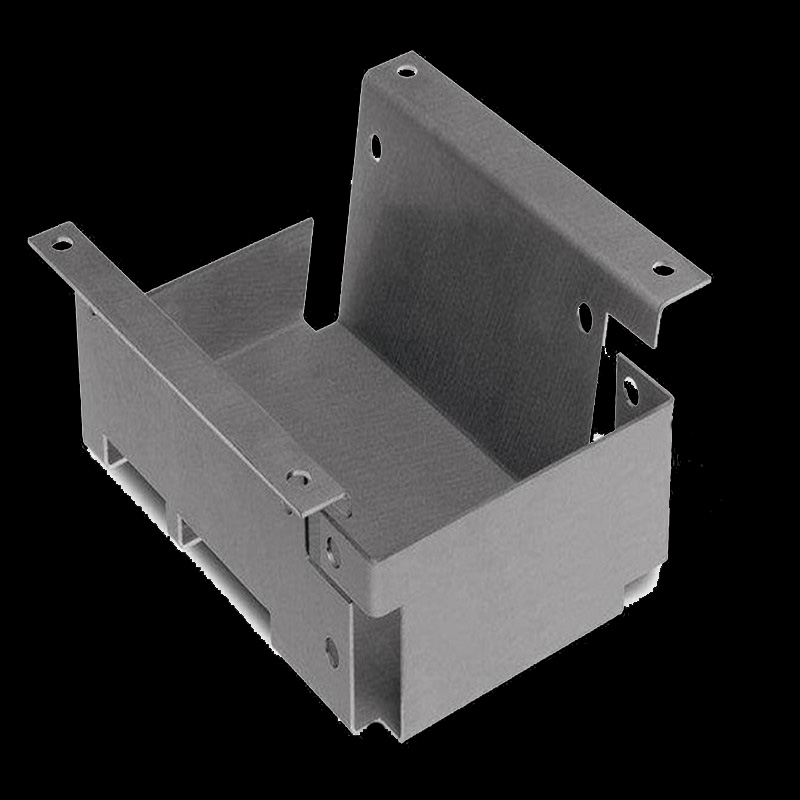

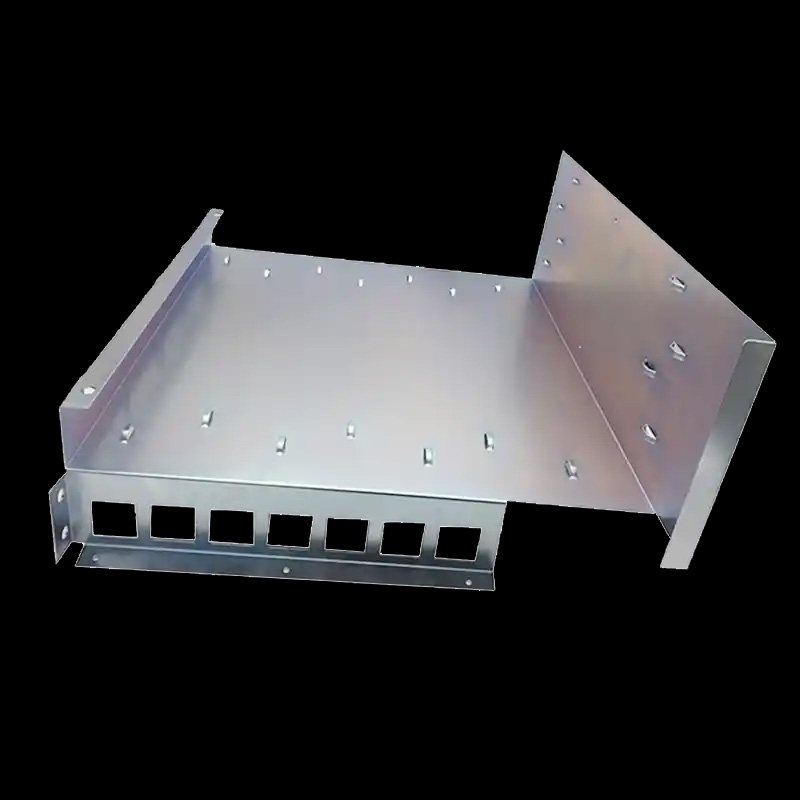

Present our completed prototype to the production project

The pictures of the parts we displayed have been approved by the customer and are subject to the customer's confidentiality agreement

18 Materials Available For Sheet Metal Fabrication

Aluminum Materials

AL6061

AL5052

AL1010

AL1060

AL6063

Stainless Steel Materials

SS304

SS316L

SS301

Mild-Steel Materials

1018

1020

Cooper Materials

T2

C1100

C1010

Alloy-Steel Materials

Cold Rolled Sheet-SPCC

electrolytic plate-SECC

Galvanized sheet-SGCC

Q235-(Steel A3)

Steel #45

Surface Treatment Available For Sheet Metal Fabrication

Oxidation:anodizing, hard anodizing, conductive anodizing

Spraying:baking paint, plastic spraying, Teflon spraying

Electroplating:chrome, zinc, black zinc, gold, silver, black nickel, tin, nickel, black chrome, decorative chrome

Others:sandblasting, silk screen, laser marking, blackening, brushing, electropolishing, passivation,powder Coating

The industries we serve

As an important metal processing product, sheet metal parts have a wide range of working principles and application fields, covering almost all industries and fields. Through our sheet metal processing and manufacturing OEM services, we can meet the needs of different industries and provide convenience and flexibility for the manufacturing of various products.

Aerospace industry: aircraft fuselage, wings, structural components, fixtures.

Electronics and medical industries: computer electronic product casings, chassis and parts, brackets, cabinets