Rapid prototyping

From design to prototype production to production, always ready to turn your ideas into reality

A prototype supplier certified by ISO 9001:2015 ensures that your project meets strict quality standards

One on one support service from the technical team, quick response to demand feedback

Experienced team of engineers and advanced production methods to deliver on time

Rapid prototyping

Sumitech is your trusted research and development partner. From CAD design to the physical prototype in your hands, and finally to your team, the speed is faster than ever before. We have developed the latest rapid prototyping technology to address your design challenges and will work with you to validate and improve your product ideas, functional testing, and engineering validation. Our rapid prototyping services include CNC prototyping, 3D printing, vacuum casting, rapid prototyping, sheet metal prototyping, and prototype finishing.

Rapid manufacturing

Sumitech is also your best manufacturing partner. We offer a range of solutions to help you expand from effective prototypes to production parts. Our rich manufacturing experience and ability to integrate resources enable us to handle the needs of any project and ensure that your parts always meet the highest quality standards. Customized rapid manufacturing services include CNC machining, plastic injection molding, metal casting, sheet metal manufacturing, and precision machining of parts

Welcome to Sumitech Special Agent Factory

We have complete prototype design and manufacturing capabilities

We can provide you with excellent quality, fast turnover, and cost-effective rapid prototyping services. We are equipped with cutting-edge prototype design and manufacturing technology, advanced industrial grade equipment, and a team of expert engineers to bring your ideas from design to market in just a few days. We are delighted to start working with you.

Tailored for you

Are you looking for professional prototyping services to help implement your ideas and assist in product development?

At Sumitech, we provide one-stop rapid prototyping design services and cost-effective rapid manufacturing services to support every process of your product development and help you enter the market faster. Do you only need one or more than 10000 units? Production grade materials? Complex geometric shapes? Strict tolerance? Are the details exquisite? Sumitech will always do its best to meet your design and manufacturing needs. Our company's mission is to help turn your ideas into reality.

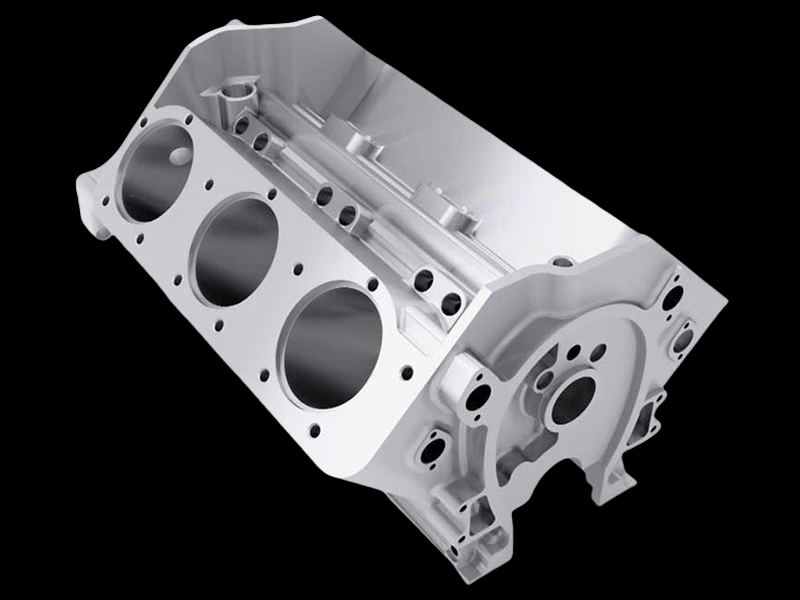

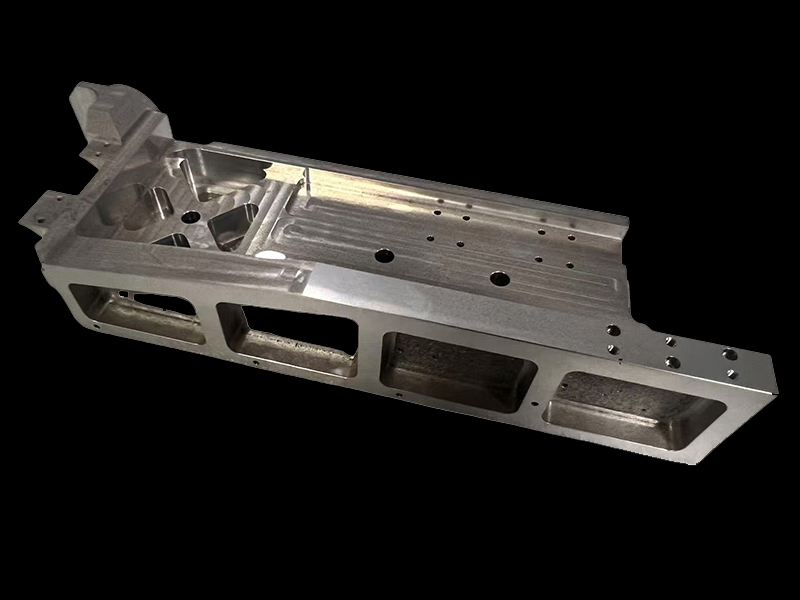

Rapid CNC machining

CNC machining is the epitome of high-precision rapid prototyping, combining speed and quality seamlessly. With swift turnarounds as a priority, it ensures exceptional accuracy, making it a preferred choice across industries.

Even in low volumes, CNC prototyping delivers rapid results without sacrificing quality. The produced parts, though prototypes, match the precision of mass production. While the cost might exceed that of 3D printing, the superior surface finish and sturdy part strength validate the investment.

- CNC Milling — Milled prototype & production parts in plastic and metal

- CNC Turning — All types of round components

- CNC Grinding — Tight tolerance and good surface

- CNC EDM — For deep pocket & sharp conners

Rapid 3D Printing

In Sumitech, our 3D printing rapid prototyping services excel in producing high-quality plastics and metals, offering a wide range of materials and finishing options. These cutting-edge additive manufacturing technologies can even transition seamlessly into production.

By eliminating the need for tooling, 3D printing ensures quick prototyping without compromising quality. Enjoy the benefits of geometric flexibility and cost-effectiveness, particularly for low-volume projects.

- FDM — Low-cost plastic parts prototyping

- SLA — Plastic parts prototyping with exceptional surface finish

- SLS — Strong prototyping parts in nylon or nylon glass

- SLM — Metal parts prototyping in steel or titanium

Rapid vacuum casting

Get to know Sumitech rapid vacuum casting service, perfect for cost-effective production of plastic parts, especially vibrant display models. Benefit from minimal tooling costs compared to injection molding and enjoy lower minimum order quantities.

Despite the parts not being exceptionally durable, rapid vacuum casting yields excellent surface finishes straight out of the mold, eliminating the need for post-processing. Plus, our silicone molds last around 20 shots, ideal for most prototyping needs

- Rigid Plastics — Such as ABS, PC, PA simulate prototype parts

- Soft Rubber — Rubber like prototypes from Shore A 30 to 90 degrees.

- Wax — Patterns for low-vlume investment casting

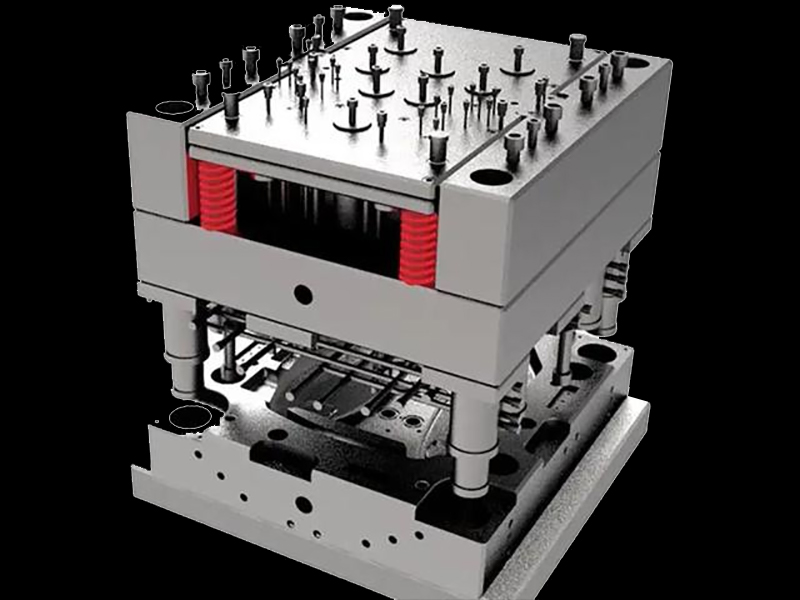

Rapid tooling

Experience Sumitech rapid tooling for molding, perfect for customers needing 100–2,000 units of injection molded parts. Enjoy fast turnarounds and cost-effectiveness compared to mass production tooling.

Rapid tooling allows for quick prototyping and testing of injection molded parts, saving months of production time. Though pricier than 3D printing, it offers plastic parts closer to production quality, ideal for functional testing.

- Plastic Injection Mold

- Die Casting Mold

- Extrusion Mold

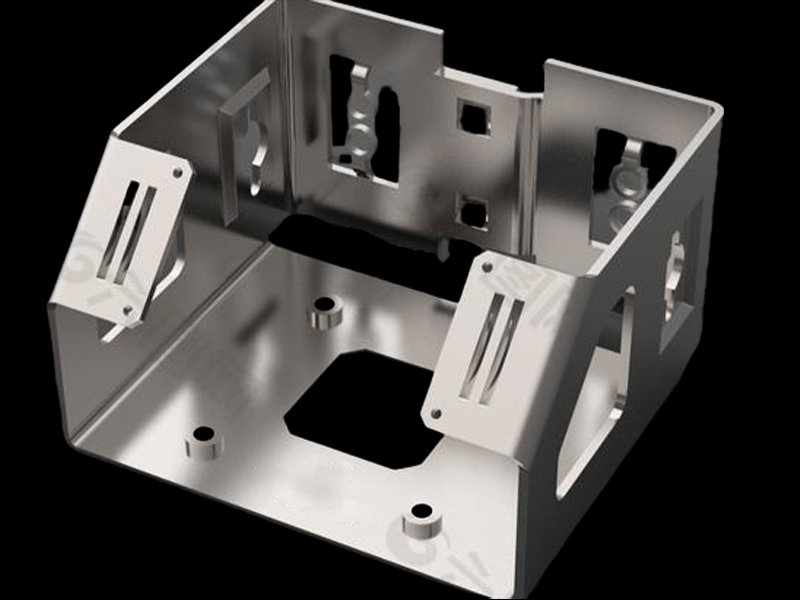

Rapid sheet metal prototyping

Sumitech rapid sheet metal prototype production service, tailored for creating sheet metal parts through versatile forming, cutting, and assembly processes.

Ideal for flat parts like brackets and enclosures, our services accommodate various sizes, including large metal parts. While setup times may be longer, sheet metal proves highly cost-effective for large and straightforward parts.

One notable advantage is the ability to later CNC machine the solid sheet metal feedstock for additional features, ensuring versatility and precision.

- Bending

- Stamping

- slicing

- Welding

Rapid metal casting

Sumitech Innovation innovative rapid metal casting services, revolutionizing metal part prototyping through affordable 3D-printed patterns.

Benefit from our exclusive partnerships with major casting companies, enabling access to low-volume prototyping orders typically unavailable to new customers.

Enjoy the advantages of near-production quality metal parts, with the potential for large sizes and rapid turnaround times. Additionally, cast parts boast exceptional tensile strength and can be further post-machined for customization.

- Pressure Die Casting

- Investment Casting

- Gravity Casting

Why choose our rapid prototyping services?

Excellent. Efficient. Economic.

These three values define Sumitech rapid prototyping services. Working closely together, we can bring your product vision to reality in a few days, at a fair price.

No minimum order quantity

We are flexible for one-off prototypes and low-volume parts. No matter the size of your order, we can handle it.

Competitive Pricing

We have built up an efficient rapid prototyping system which allows us to offer competitive prices that can match any offer.

Rapid Turnaround

Our capacities allow us to finish your rapid prototyping projects in days.

Experienced Engineers

Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

Tight Tolerances

We service the aerospace and medical industries and can produce precise parts with tight tolerances.

Wide Range of Materials

We serve a wide range of clients and can offer a variety of rapid prototype materials and finishes.

Material Options for Rapid Prototyping

We handle all types of materials including metals, many types of thermoplastics, elastomers, etc. We help our customers select and purchase the right type of material for their application needs.

Metals

- Aluminum

- Stainless Steel

- Tool Steel

- Alloy Steel

- Brass

- Copper

- Titanium

- Mild Steel

- Invar

- Inconel

Plastics

- ABS

- Polypropylene

- POM

- Acaylic

- PEEK

- Polycarbonate

- Nylon

- Polyethylene

- PVC

- PET

- PTFE

- PA+GF30

- HDPE

- PEI(Ultem)

- PMMA

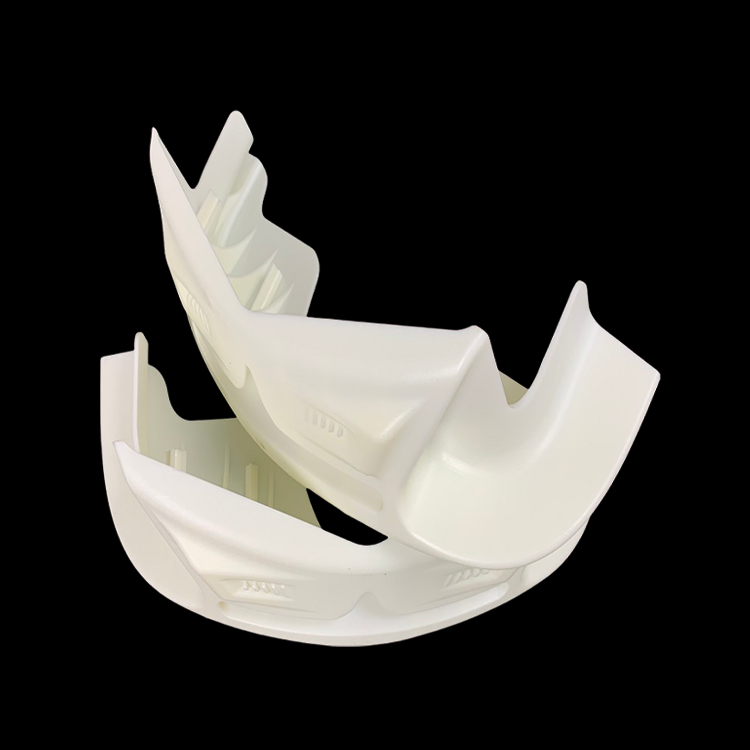

Present our completed prototype to the production project

The pictures of the parts we displayed have been approved by the customer and are subject to the customer's confidentiality agreement

Only a portion was displayed. If you would like to learn more about the cases, please contact us!

FAQ

No minimum quantity! sumitech offers both prototype and short to mid-production machining services.

For 3D drawings, we prefer STEP, IGES or X_T formats. For 2D drawings, we prefer PDF format, with dimensions toleranced if possible.

General machining tolerances for metals are +/- 0.005 inches (+/- 0.127 mm) per ISO 2768 unless otherwise specified. Plastics and composites are +/- 0.010 inches (+/- 0.254 mm).

Precision machining tolerances as low as ±0.002inches (0.005mm). AT can manufacture and inspect tight tolerances to your drawing specifications.

Prototype lead time is 2 to 3 weeks, production run lead time is 4 weeks. Emergency and expedited services are available.