Who We Are

Sumitech precision machinery technology (Dongguan) Co., Ltd. was established in December 2013, located in a famous of hardware Changan town, Dongguan City.

As a professional precision machining manufacturer, Sumitech specialize in providing precision parts machining, 5-axis parts machining complex parts machining, Invar alloy parts machining Titanium alloy parts machining, Engineering plastics parts machining, Non-standard parts machining for medical, semiconductor, energy, auto, communication, and some other areas. We can also provide one-stop modular assembly service. With years of technical accumilation, we have rich experience in precision machining and surface treatment for titanium alloy, Invar alloy and engineering plastic.

In order to providing better quality, we introduce Germany DMG 5-axis,4-axis, 3-axis machining center, and CNC lather, grinding machine. milling mchine, drilling machine, wire cutting and other high precision production equipment.

We also have high-end testing equipment including Germany ZESSI Contura G2, VMC 432, Height Gauge, Hardness tester, roughness tester, Coating tester, HRC hardness tester, ect.

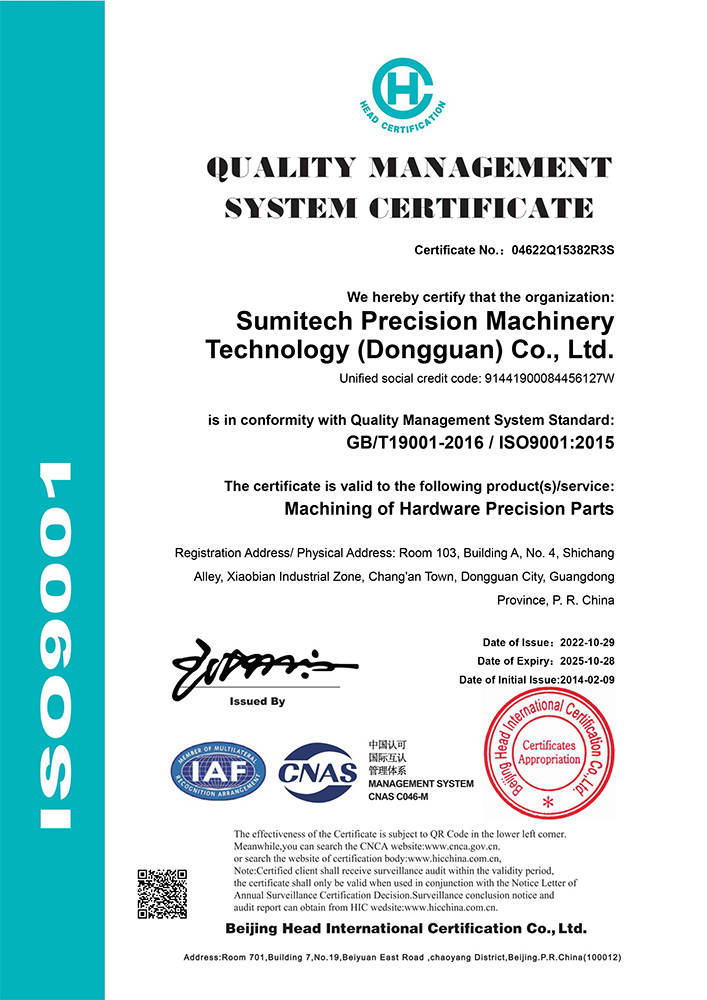

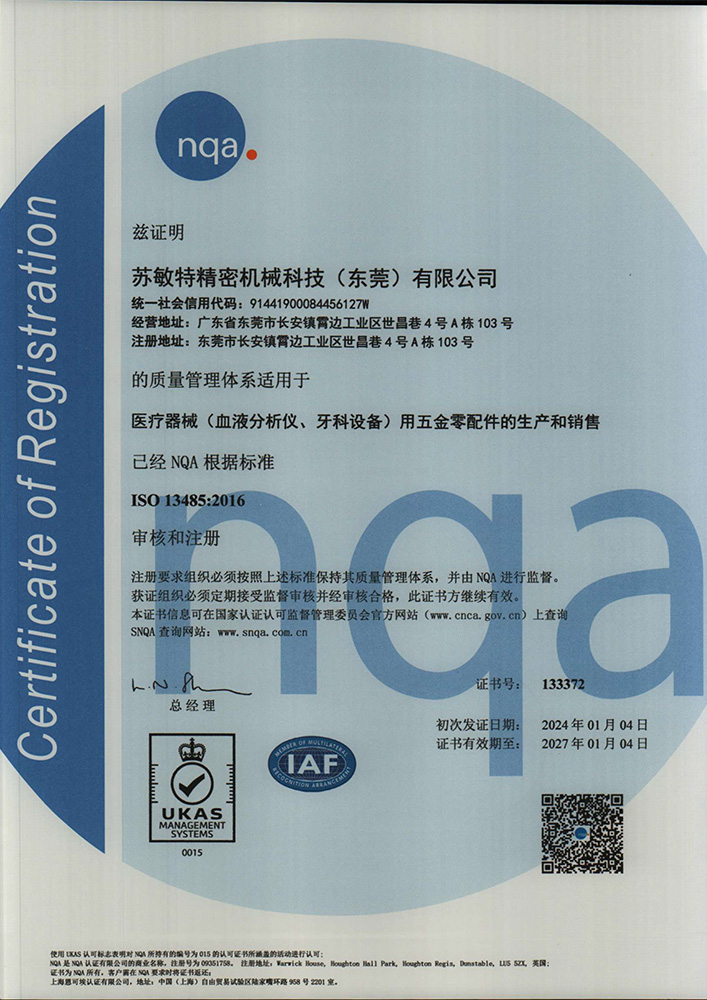

Sumitech obtained ISO 9001 international certification and ISO 13485 international medical certification in 2019.

Fires-class management technical team, high-end production equipment, precision testing machines, prefect ISO management system, and the craftsmanship spirit of striving for the best allow us to provide the best quality and the best services.

Hope our sincere service could win you trust and support!

Strength manufacturer

Production scale

Professional team member

Imported production equipment

High-end testing equipment

Online service

Our certification

These certifications are not only proof, but also a solemn commitment to customers. We will adhere to these strict standards and ensure that our products and services remain industry-leading through continuous improvement and innovation.

- ISO9001:2015

- ISO13485:2016

- China High-tech Enterprise Certification

Why Choose Us

1.Incredible Capabilities

Our extensive production capabilities enable us to satisfy all your project requirements from prototype to production.

2.On-time Delivery

We value punctuality and understand the importance of on-time delivery, so we will create a production schedule for your project.

3.Exceptional Experience

You can expect an exceptional customer experience with our expert assistance and prompt responses to your questions.

Step into our workspace

Here, we transform ideas into practical and feasible solutions, each process reflecting a commitment to excellence

FAQ

No minimum quantity! sumitech offers both prototype and short to mid-production machining services.

For 3D drawings, we prefer STEP, IGES or X_T formats. For 2D drawings, we prefer PDF format, with dimensions toleranced if possible.

General machining tolerances for metals are +/- 0.005 inches (+/- 0.127 mm) per ISO 2768 unless otherwise specified. Plastics and composites are +/- 0.010 inches (+/- 0.254 mm).

Precision machining tolerances as low as ±.0002″ (0.005mm). AT can manufacture and inspect tight tolerances to your drawing specifications.

Prototype lead time is 2 to 3 weeks, production run lead time is 4 weeks. Emergency and expedited services are available.

Today, let's start a new project