5 axis cnc machining

Focusing on fields such as medical, semiconductor, aviation, energy, automotive, and communication.

Provide precision parts machining, five axis linkage parts machining, complex parts machining,machining of Inwa alloy parts, titanium alloy parts machining, engineering plastic parts machining, stainless steel parts machining, and non standard parts machining.

Obtained:

ISO9001:2015

ISO13485:2016 certification

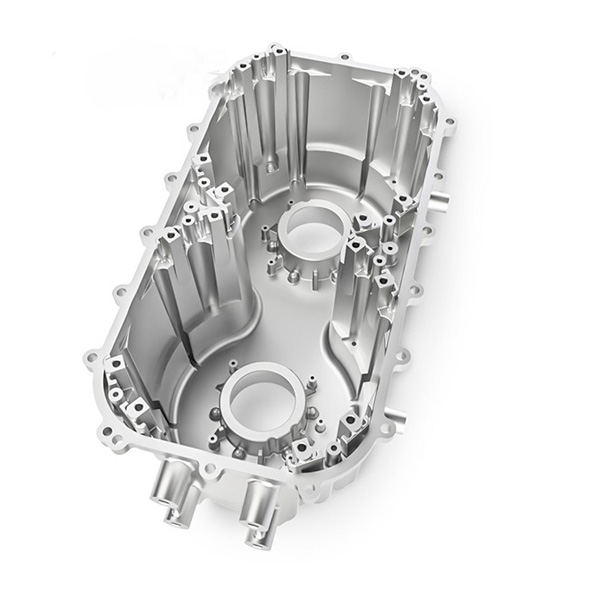

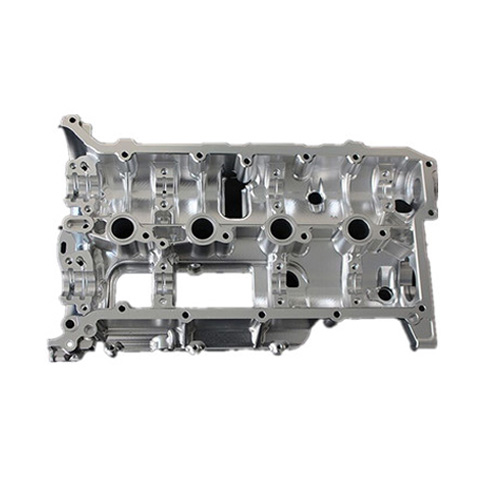

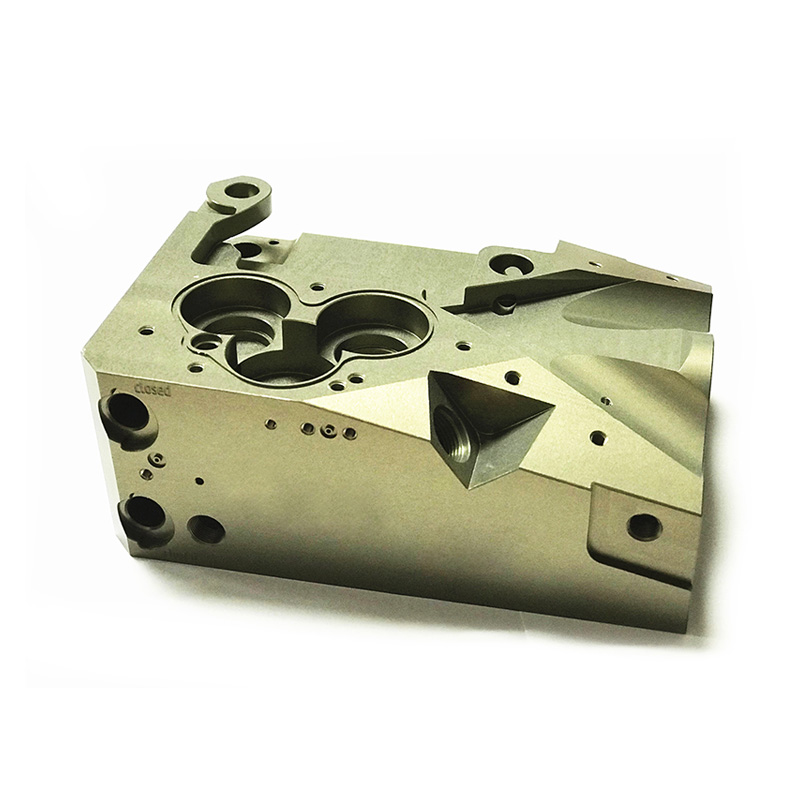

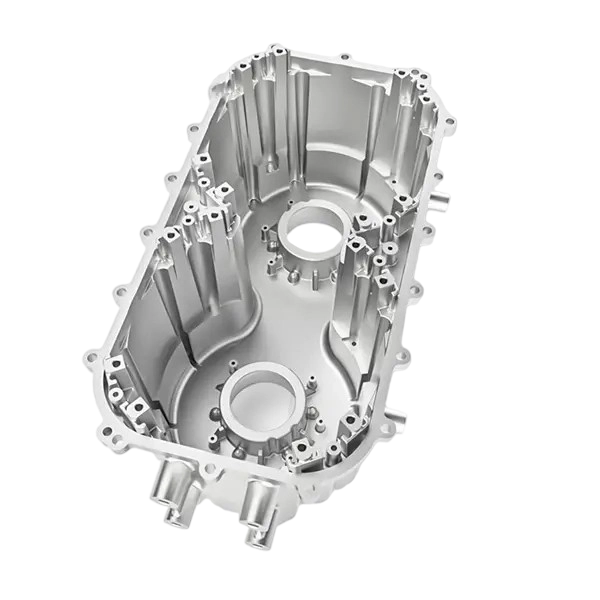

Product Display

Various materials and shapes all can customized machining

We specialize in five axis machining materials

1、 Metal materials

Conventional metals

Steel:

Carbon steel, stainless steel (such as 316L), cast iron, etc., widely used in automotive parts (gearbox housing, engine cylinder block) and mold manufacturing.

Light metals:

aluminum alloys (6061, 5052), magnesium alloys, etc., suitable for aerospace structural components and consumer electronics heat sinks.

High performance alloy

Titanium alloy:

used in scenarios that require high strength and corrosion resistance, such as aircraft engine blades and medical devices (such as orthopedic implants).

Nickel based alloys (such as Inconel 718):

Their high temperature resistance makes them the preferred choice for turbine blades and energy equipment impellers.

2、 Non metallic materials

Engineering plastics

PEEK, nylon, ABS:

used for medical equipment, lightweight shells, etc., to meet the requirements of biocompatibility and wear resistance.

PP, POM:

Suitable for parts such as impellers and propeller blades that require chemical corrosion resistance.

Composite materials

Carbon fiber reinforced material:

used for aerospace components (such as wings) and high-end sports equipment, combining lightweight and high strength.

Fiberglass composite materials:

commonly used in lightweight automotive components and industrial molds.

Special ceramics

Silicon nitride and silicon carbide: used for high-temperature wear-resistant parts (such as aviation engine sealing rings) and energy equipment components.

3、 Special materials

High-temperature alloy

Hastelloy, duplex stainless steel, etc. are used for valves and chemical equipment in extreme environments.

Hard materials

Hard alloy:

requires diamond coated cutting tools for precision molds and cutting tools.

Sumitech material processing advantages

Adaptability to complex structures:

Multi angle surfaces (such as turbine blades and propellers) can be machined through five axis linkage technology.

High precision compatibility:

Suitable for fine machining of brittle materials (graphite, ceramics), cutting parameters need to be optimized to avoid cracking.

We focus on five axis machining, and with multi axis linkage and high-precision characteristics, we can meet diverse needs from metals to composite materials, widely used in high-end manufacturing fields such as aerospace, medical, and automotive.

Advantages of sumitech five axis linkage machining

1. Technical capabilities and equipment advantages

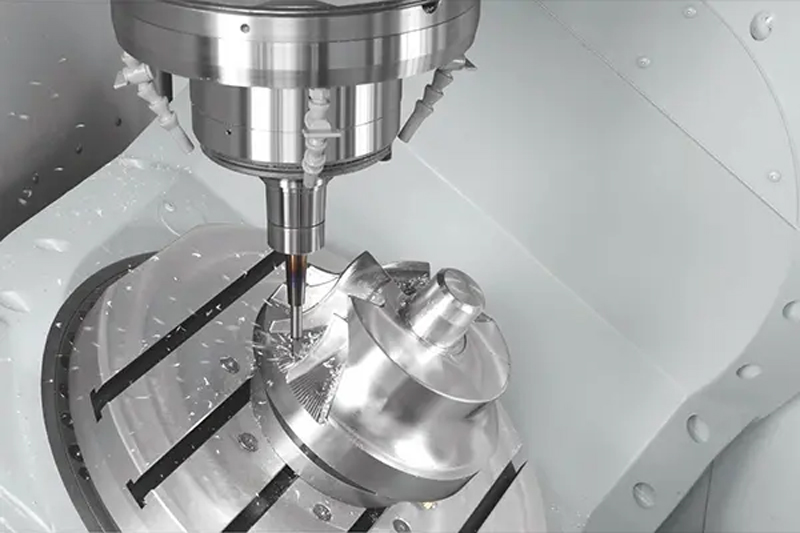

High precision multi axis linkage

The factory is equipped with international brands such as DMG MORI and MAZAK five axis linkage machining centers, which support continuous processing of complex surfaces with an accuracy of ± 0.005mm, meeting the strict tolerance requirements in aerospace, medical equipment and other fields.

Multi sided processing for one-time molding

Through five axis linkage technology, the workpiece can be machined on five sides in one clamping, avoiding the repeated positioning errors in traditional processes and ensuring the overall consistency of the parts (such as high-precision parts such as mold cavities and impeller blades).

Our factory adopts a five axis machining center imported from Germany, which completes multi-faceted machining of complex parts through one clamping, reducing clamping errors by more than 30% and significantly improving the assembly accuracy of key components such as turbine blades.

2. Production efficiency improvement and cost optimization

Shorten the processing cycle

Five axis machining can directly use tool side edges to cut complex contours, reducing layered milling and subsequent polishing processes, and increasing efficiency by more than 50% compared to traditional three-axis machining.

Reduce overall costs

Reducing the number of fixtures, manual intervention, and scrap rate, for example, when machining deep cavity parts, high rigidity cutting with short tools can reduce tool wear by 20% -30%.

For automobile mold manufacturing, five axis machining reduces the machining cycle from 3 days to 1 day by optimizing the tool path, resulting in a 15% overall cost reduction.

3. Processing capability of complex parts

Breaking through geometric limitations

Support complex structures that traditional equipment cannot process, such as impellers, propellers, and irregular surfaces, to solve technical problems such as deep cavities, inverted buckles, and thin walls.

Flexible production

Can quickly switch processing tasks and adapt to small batch, multi variety order requirements (such as customized precision parts, prototype development).

Successfully processed titanium alloy engine components for aerospace clients, achieving stable molding of 0.1mm thin-walled structures through five axis linkage technology, with a yield rate of 99%.

4. Quality control and process advantages

Surface quality optimization

By dynamically adjusting the tool angle, zero speed cutting at the center of the ball head tool is avoided, ensuring a surface smoothness Ra ≤ 0.8 μ m and reducing subsequent polishing processes.

Online detection and compensation

Integrating Renishaw probes for real-time monitoring of machining accuracy, automatically correcting tool wear errors, and ensuring stability in mass production.

Combined with an online detection system, real-time error correction is carried out during the processing, and the critical dimension qualification rate is increased to 98.5%.

5. Industry Applications and Successful Cases

Focus on high-end fields

Rich project experience in industries such as aerospace, medical equipment, and automotive molds, and cooperation with well-known brands to obtain certification qualifications (such as ISO 9001, ISO 13485).

Serving the top 10 medical device companies worldwide, processing over 500 sets of orthopedic implant molds, reducing delivery cycles by 30%, and earning the title of ‘Best Technology Supplier’ from our customers.

6. Additional Services and Competitiveness Enhancement

Customized solutions

Provide full technical support from design optimization, process simulation to post-processing to help customers reduce research and development risks.

Fast response and after-sales support: commitment to 24-hour technical response

Provide demand

We can achieve your idea