Plastic parts processing services

We hope to provide you with the best customized processing and the best service.

Committed to achieving the highest machining accuracy and adhering to the strictest standards.

From a single prototype to the production of the largest batch of components, providing full-size inspection reports.

Sumitech Plastic Precision Processing Advantages

1、 Core technology and advanced equipment

Intelligent production line:

equipped with German imported injection molding machines and automated assembly lines, ensuring accuracy of ± 0.01mm and improving product consistency.

Innovative technology:

Mastering micro foaming, gas assisted molding and other processes, reducing material consumption by 15%, suitable for high-end fields such as automotive lightweight components.

Rapid mold development:

Using 3D printing technology, the mold delivery cycle is shortened to 7 days, supporting complex structural design.

2、 Strict quality control system

Full process inspection:

From raw material entry (through ISO 9001 certified suppliers) to finished product shipment, 12 quality inspection processes are implemented, with a yield rate of ≥ 99.5%.

Laboratory support: Equipped with spectral analyzer and tensile testing machine to ensure that material properties comply with ASTM/GB standards.

Traceability system:

Each batch of products can be traced back to the production time, machine number, and operator, and a complete quality report can be provided within 48 hours.

3、 Efficient production and cost optimization

Large scale production:

With a daily production capacity of 500000 pieces, it supports urgent order delivery services and has a delivery cycle 30% faster than the industry average.

Lean management:

Real time monitoring of production through MES system, reducing energy consumption by 20% and inventory backlog by 35%.

Supply chain integration:

Cooperate with first tier suppliers such as Sinopec, with an annual procurement volume of over 10000 tons and raw material costs 8% lower than market prices.

4、 Customized services and deep industry cultivation

Cross industry experience:

Serving the fields of healthcare, automotive, electronics, etc., with a cumulative development of over 3000 customized molds.

Integrated design:

Provides one-stop service from structural design, mold development, to mass production, with free sampling and 3-day delivery of prototypes.

Quick response mechanism:

24-hour customer service+engineering team, on-site resolution of quality issues within 48 hours, providing lifelong technical support.

5、 Regional and logistics advantages

Industrial cluster effect:

Located in the Yangtze River Delta plastic industry belt, covering 500 supporting enterprises within 30 kilometers, reducing collaboration costs.

Multimodal transportation network:

self owned fleet+port cooperation, domestic delivery within 48 hours, direct export containers to ports, shortened shipping cycle by 2 days.

For the new energy vehicle project: complete the design to mass production within 3 months, reduce component weight by 20%, and help customers reduce energy consumption by 12%.

For the European eco-friendly tableware order, using PLA material, 1 million pieces were delivered in 6 weeks, certified by TUV, and the customer repurchase rate increased by 40%.

Complete certification:

Passed ISO 13485 (medical) and other certifications, supporting high-end market access.

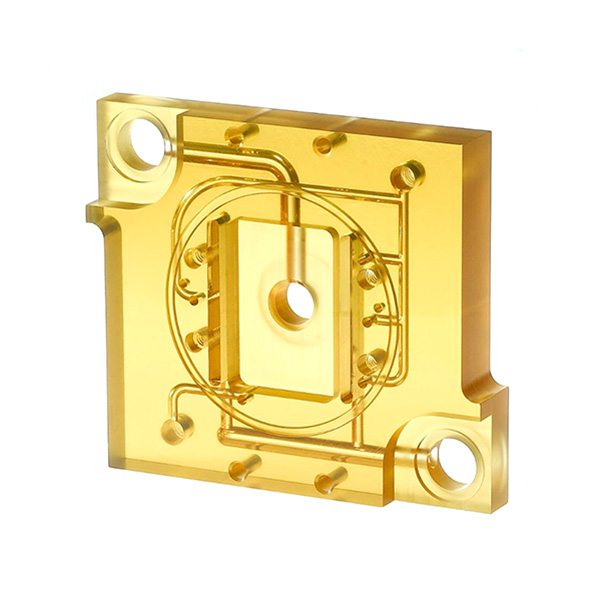

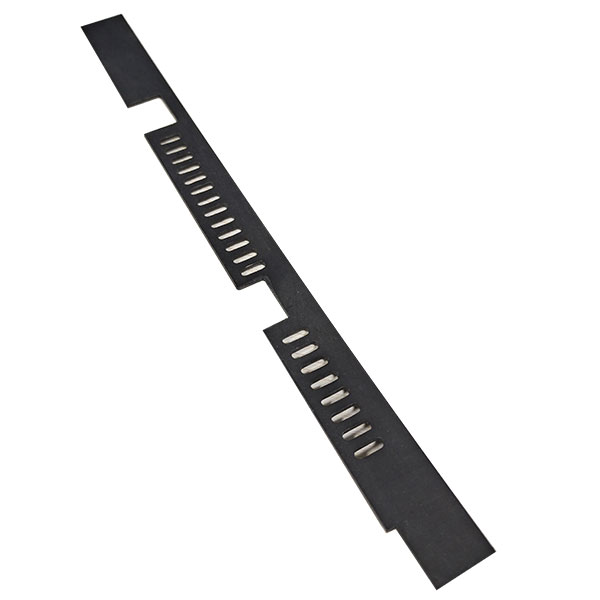

plastic machining

cnc plastic cutting

Precision plastic processing

Precisionp lastic machining

plastic cnc machining

custom cnc plastic

milling plastic

plastic cnc milling

Plastic Parts Machining

Plastic Parts Processing

cnc plastic

PEEK Medical industry part

plastic machining services

cnc plastic machining

plastic cnc machining

plastic cnc

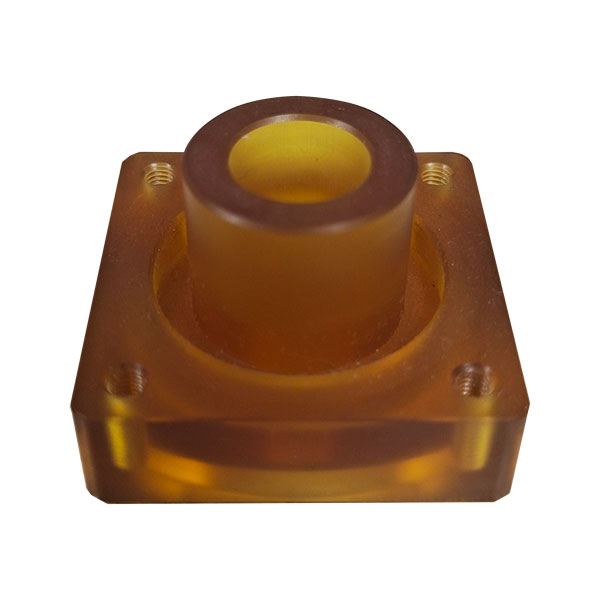

POM Medical industry 5axis machining part

PTFE Medical industry 4axis machining part

POM Medical industry 4axis machining part

Do you need a project quotation? Contact us now via phone, email, or contact form