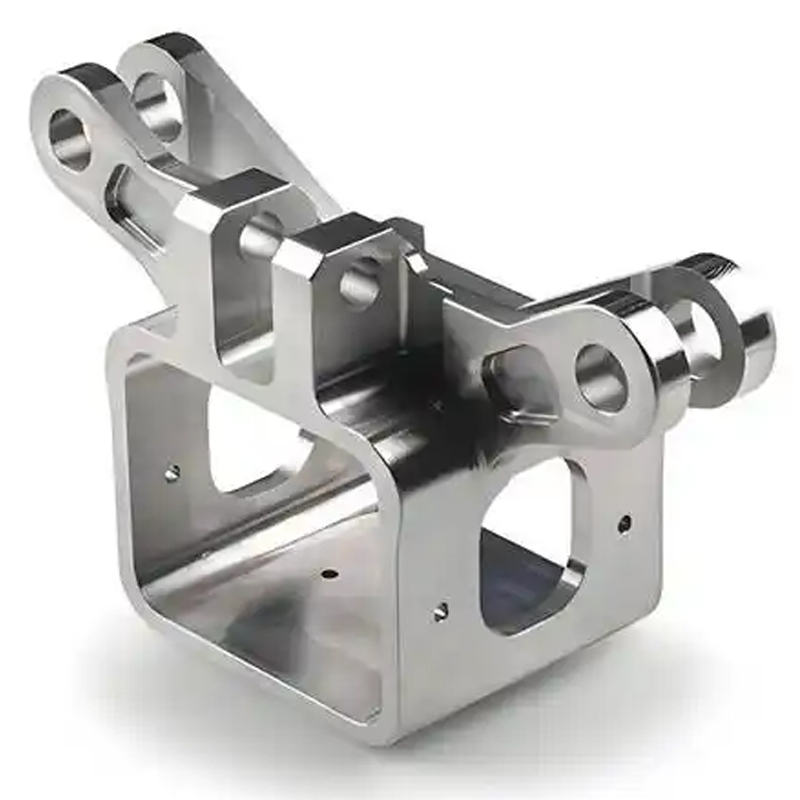

Stainless steel parts processing services

We hope to provide you with the best customized processing and the best service.

Committed to achieving the highest machining accuracy and adhering to the strictest standards.

From a single prototype to the production of the largest batch of components, providing full-size inspection reports.

Sumitech stainless steel precision machining advantages

1、 High precision machining capability

Cutting edge equipment support: equipped with German TRUMPF laser cutting machine (accuracy ± 0.03mm) and Swiss BYSTRONIC bending machine (repeat positioning accuracy ± 0.01 °), capable of processing materials with thicknesses ranging from 0.5-50mm to 304/316L.

Complex process coverage: supports deep stretching (aspect ratio ≤ 3:1), mirror polishing (Ra ≤ 0.1 μ m), seamless welding (argon arc welding+TIG welding) and other processes, meeting medical grade cleanliness requirements.

Customized solution: Flexible production of single piece and small batch, 24-hour quotation for 3D drawings, and delivery of samples within 3 days (supporting heterogeneous material combinations such as stainless steel aluminum composite structures).

2、 Strict quality control and international certification

Full process testing system: raw material traceability (providing SGS material reports)+process monitoring (penetrant testing/hardness testing)+finished product full inspection (three coordinate measurement accuracy ± 1.5 μ m). Certified according to ISO 13485 (Medical Devices). Salt spray test ≥ 2000 hours (316L material), electrolytic polishing process to improve surface anti pollution, in compliance with FDA food contact standards.

cnc machining stainless steel

cnc stainless steel

cnc steel

cnc steel cutting

Stainless steel 303 parts

Stainless steel 316L parts

stainless steel cnc machining

steel cnc machining

Stainless Steel Machining

steel cnc

cnc stainless

stainless steel cnc cutting

Do you need a project quotation? Contact us now via phone, email, or contact form