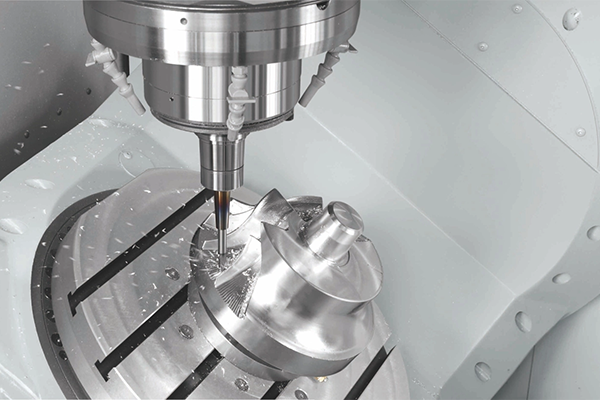

CNC machining

Focusing on fields such as medical, semiconductor, aviation, energy, automotive, and communication

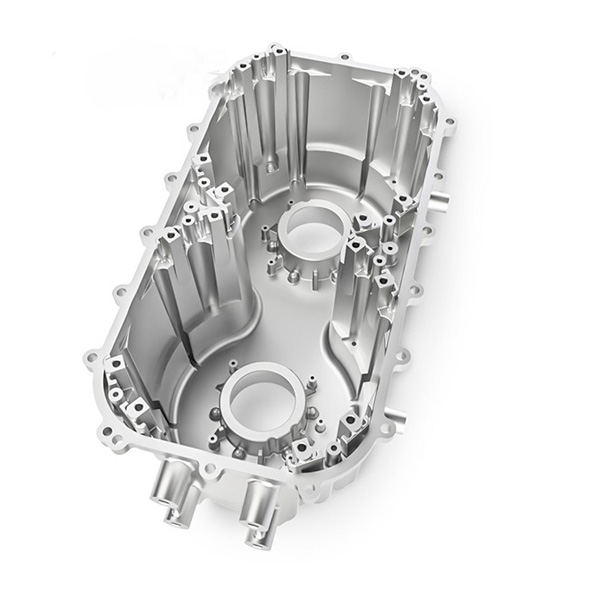

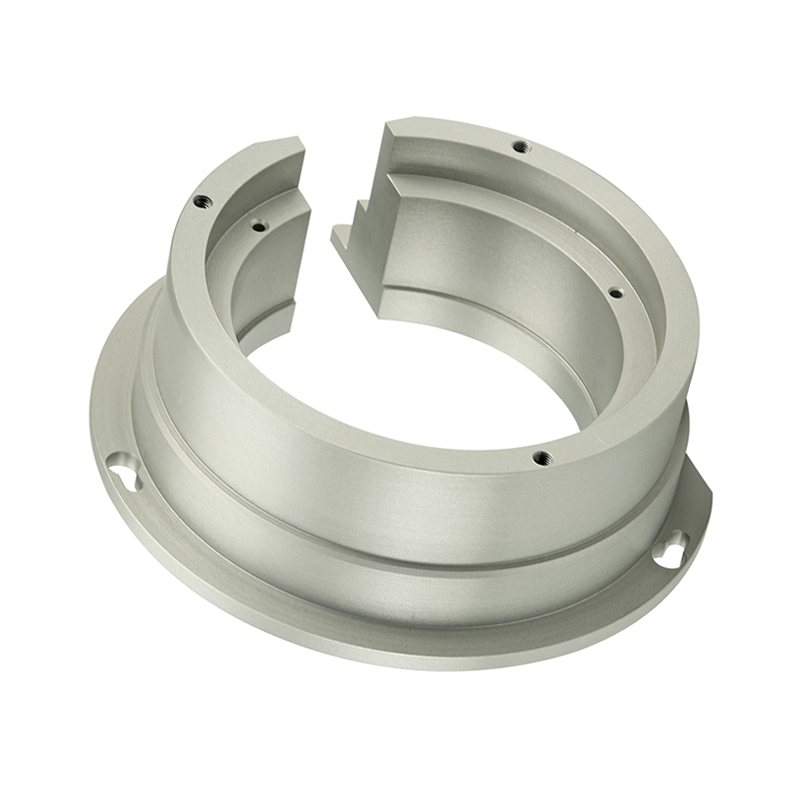

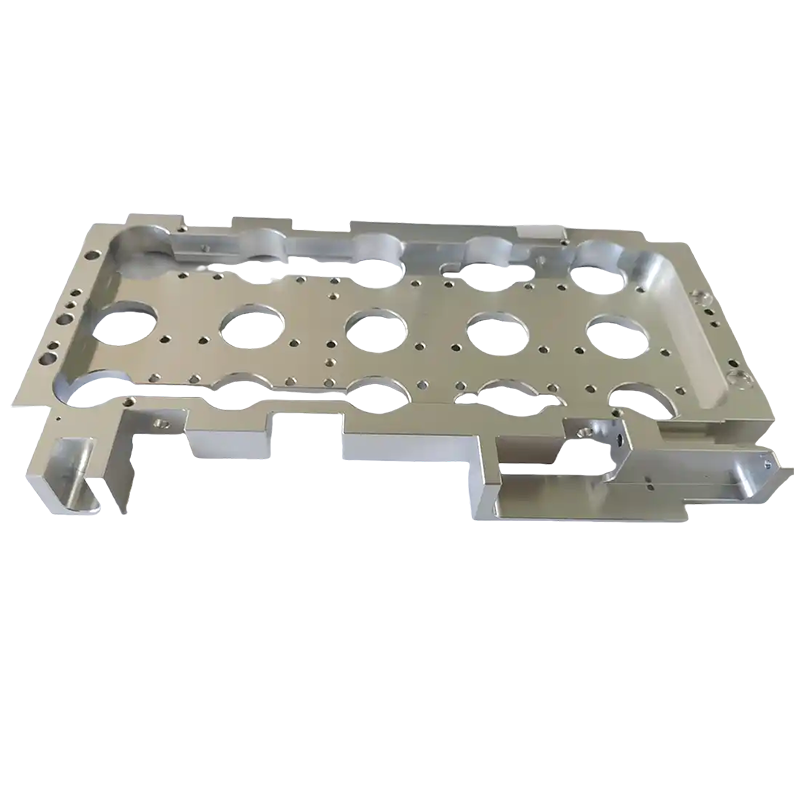

Provide precision parts processing, five axis linkage parts processing, complex parts processing, Processing of Inwa alloy parts, titanium alloy parts processing, engineering plastic parts processing, stainless steel parts processing, and non-standard parts processing

Obtained:

ISO9001:2015

ISO13485:2016 certification

Provide CNC machining services on demand

For new products and customers, confirm the machining process plan based on different industry requirements and material conditions, prepare process documents, and determine the machining process flow; Select the most suitable production equipment for different parts to achieve the most efficient production efficiency; On site CNC process debugging to solve on-site machining process problems; Improve existing processes or fixtures to enhance production efficiency and product quality; Design practical and efficient tooling fixtures, and conduct audits, certifications, and final product acceptance of outsourced tooling fixture design schemes; At the same time, we will provide professional advice to customers in different fields based on our rich CNC professional knowledge combined with our company's high-end high-precision equipment. Especially for non professional customers, we have repeatedly suggested to achieve the effect of saving costs and accelerating sample progress for customers. And received unanimous praise.

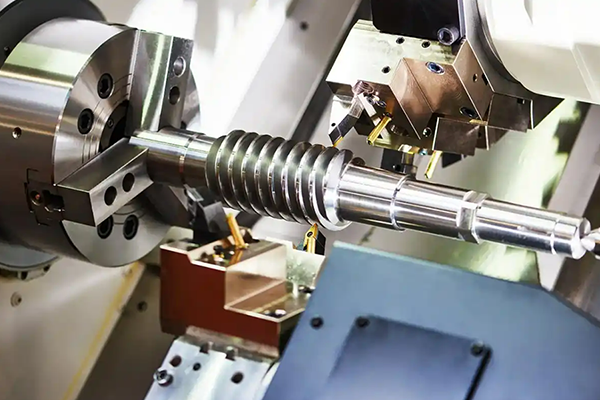

Lathe machining is a part of mechanical machining, mainly in two forms: one is to fix the turning tool and process the unformed workpiece during rotation; Another method is to fix the workpiece and perform precision machining by high-speed rotation of the workpiece and horizontal and vertical movement of the cutting tool (tool holder).

CNC lathes are capable of processing complex rotating body shapes. Numerical control milling machines can process complex shapes and features. The milling and boring machining center can perform three-axis or multi axis milling and boring machining, used for machining molds, gauges, molds, thin-walled complex surfaces, artificial prostheses, blades, etc

When precision machining parts with complex geometric shapes, it is necessary for the machining tool to be able to position and connect in five degrees of freedom. It is commonly used in the aerospace field to machine body parts, turbine parts, and impellers with free-form surfaces.

4 axis machining is a CNC machining technology widely used in fields such as aerospace, automotive manufacturing, medical equipment, and electronic products. For example, four axis machining technology can be used for complex turbine blades in aerospace, engine components in automotive manufacturing, precision parts in medical equipment, and small precision parts in electronic products

3 axis machining usually refers to the use of three shafts with different directions of variable speed linear motion for machining, which can only process one surface at a time, and is more suitable for machining disc components. The processed products have high precision in verticality, concentricity, and other aspects.

Used for cutting inner and outer cylindrical surfaces, inner and outer conical surfaces with arbitrary cone angles, complex rotating inner and outer surfaces, and cylindrical and conical threads of shaft or disc parts, and can perform cutting, drilling, expanding, reaming, and boring.

Complete The Delivery of Parts Project Presentation

The parts pictures we display have been authorized by the customer and are subject to the customer confidentiality agreement.

CNC machining materials and surface treatment

Stainless steel series (316/316L/316F/303/304/420, etc.), aluminum alloy series (AL6061/5083/7075/2A12, etc.), alloy series (Invar alloy, cobalt nickel alloy, 718, etc.), engineering plastic series (PEEK/POM/ABS/PTFE, etc.), glass fiber series (G10/FR4, etc.), carbon fiber series, copper material series (C1100/black copper, brass, tin bronze, etc.)

The above materials are all the expertise and experience of our company, which can select different cutting tools and create different processing programs according to different materials.

Surface treatment: a complete set of high-quality surface treatment processes.

Gold plating, silver plating, tin plating, nickel plating, chromium plating, oxidation, sandblasting, screen printing, laser engraving, electroless nickel deposition, spraying, chemical cleaning, vacuum packaging, heat treatment, wire drawing, passivation, chelating salts, conductive oxidation, powder coating, conductive paint, etc.

Precision machining capability

While investing heavily in high-end production equipment and introducing multiple high-end testing devices, sumitech has a clearer understanding that the long-term development of the enterprise requires a sound management system. Under the ISO9001 and ISO13485 quality and management system standards, sumitech strives to provide customers with complete and traceable services.

FAQ

No minimum quantity! sumitech offers both prototype and short to mid-production machining services.

For 3D drawings, we prefer STEP, IGES or X_T formats. For 2D drawings, we prefer PDF format, with dimensions toleranced if possible.

General machining tolerances for metals are +/- 0.005 inches (+/- 0.127 mm) per ISO 2768 unless otherwise specified. Plastics and composites are +/- 0.010 inches (+/- 0.254 mm).

Precision machining tolerances as low as ±0.002inches (0.005mm). AT can manufacture and inspect tight tolerances to your drawing specifications.

Prototype lead time is 2 to 3 weeks, production run lead time is 4 weeks. Emergency and expedited services are available.

Today, let's start a new project