Precision lathe machining services

- Maintain the strictest tolerance of ± 0.002 mm during the production process

- Timely delivery within 3 days or less

- Save over 60% of costs

- Can turn over 200 types of materials, including metal and plastic

- Strict tolerances and concentricity are our manufacturing standards

Lathe machining case presentation

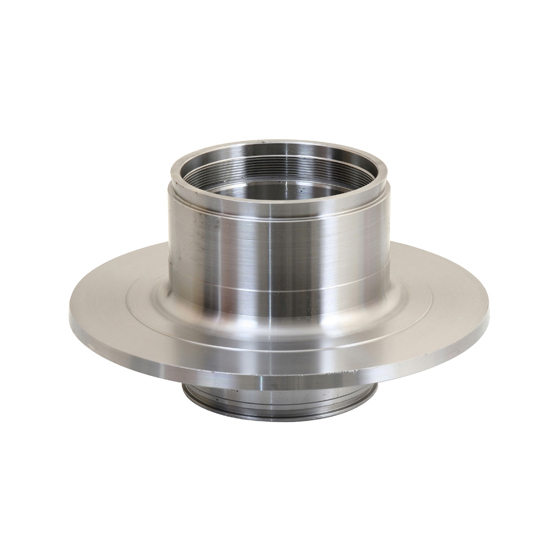

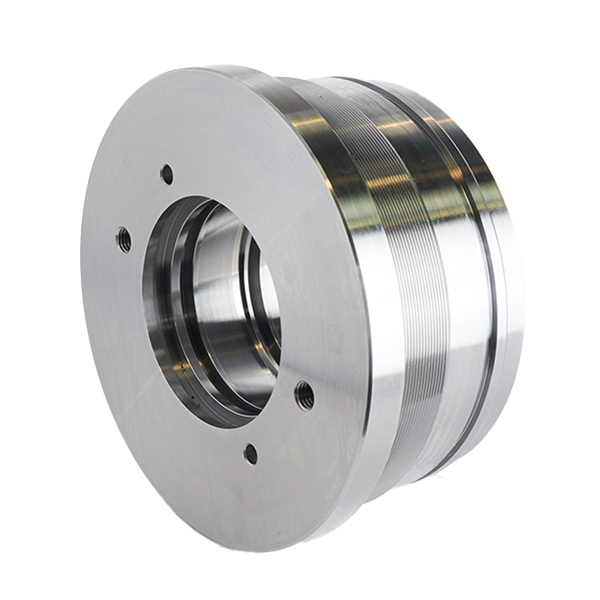

CNC lathe parts

lathe machining parts

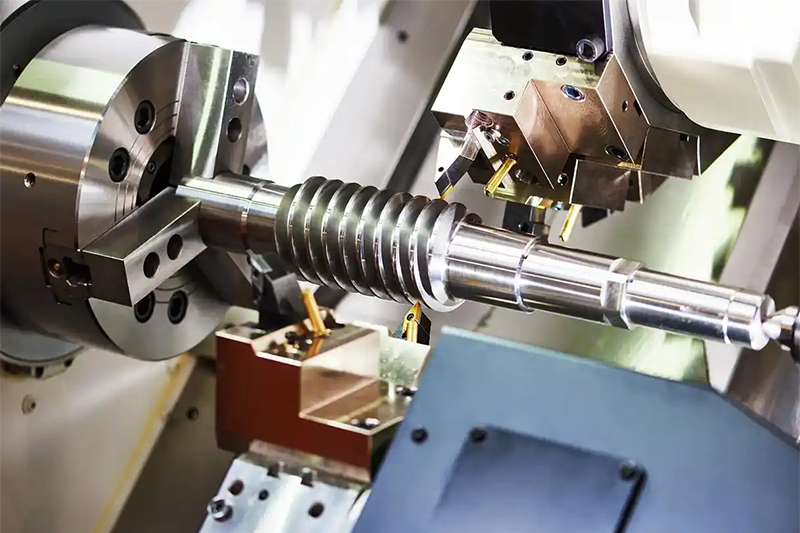

lathe machining

cnc machining of parts

cnc lathe

cnc lathe machining

lathe services

cnc lathe machining parts

cnc lathe machining parts

precision lathe machining

lathe machining services

turning lathe parts

custom lathe parts

precision cnc lathe machining

turning lathe parts

machine tool machining

The materials we specialize in lathe machining include:

一、 Metal materials

Steel category

1、Carbon steel (45 #, 20 #, 40Cr, etc.), stainless steel (304, 316, etc.), alloy steel, cast iron, etc

2、Free cutting steel (materials with high sulfur and phosphorus content).

Copper and alloys:Copper, brass, and other copper alloys .

Aluminum and alloys:Aluminum alloys, alloy aluminum, zinc alloys, etc. are particularly suitable for lightweight demand scenarios such as aviation accessories.

Other metals:High performance materials such as titanium alloys and nickel based alloys.

二、 Non metallic materials

Plastic category

Engineering plastics such as polytetrafluoroethylene (PTFE), polyoxymethylene (POM), ultra-high molecular weight polyethylene (UHWM), acrylic, etc.

Other composite materials

Special materials such as graphite, laminated boards, and laminated circles.

三、 Special materials and processes

The lathe can also process irregular structural parts (such as triangles and diamonds), as well as complex parts with multiple material combinations (square and circular combination structures).

The processing of the above materials requires adjusting process parameters (such as tool selection, speed, feed rate, etc.) based on specific performance to ensure accuracy and efficiency.

Advantages of Sumitech lathe machining

一. Having high-precision equipment and technology

1、Imported equipment from Switzerland/Germany, processing accuracy of ± 0.001mm, multi axis linkage capability, and five axis linkage processing.

2、Special process capabilities such as deep hole machining, thread machining, and complex surface machining.

二. Process optimization capability

1、Process design team experience: Over 10 years in an engineering team.

2、Software assisted capabilities: CAD/CAM programming, simulation and emulation.

三. Strict quality control

1、Testing equipment (such as coordinate measuring instruments, laser detectors).

2、Quality certification (such as ISO 9001, IATF 16949).

3、Qualification rate data (such as a yield rate of over 99.5%.

四. Quick response and delivery

1、Production cycle (such as small batch delivery within 72 hours).

2、Flexible production capacity (supporting customized orders).

五、 Cost Control Advantages

1、Large scale production reduces individual unit costs.

2、Optimization of raw material supply chain (stable procurement channels).

Quote Now to Start Your CNC Machining Project

Complete CNC machining services from prototype to production ensure high quality, fast delivery and competitive prices.