Titanium alloy parts processing services

We hope to provide you with the best customized processing and the best service.

Committed to achieving the highest machining accuracy and adhering to the strictest standards.

From a single prototype to the production of the largest batch of components, providing full-size inspection reports.

Sumitech factory titanium alloy processing advantages

1、 Cutting edge material processing capability

Special equipment cluster: equipped with German DMG five axis linkage machining center (positioning accuracy ± 0.003mm), electron beam welding machine (vacuum degree ≤ 5 × 10 ⁻⁴ Pa), ultra precision wire cutting (surface roughness Ra ≤ 0.2 μ m), suitable for medical/aerospace grade titanium materials such as TC4, TA15, Ti-6Al-4V ELI, etc.

Breakthrough in complex processes: Achieving thin-walled machining (thickness 0.3mm ± 0.02mm), deep hole drilling (depth to diameter ratio 15:1), mirror polishing (Ra ≤ 0.05 μ m), solving industry problems such as titanium alloy sticking and thermal deformation.

Heat treatment technology: Vacuum annealing furnace (temperature control ± 3 ℃) eliminates residual stress, and solid solution strengthening treatment in the β phase zone improves component fatigue strength by ≥ 30%.

2、 Strict industry certification and quality control

Full process quality control: Raw material batch traceability (AMS 4928/GB/T 2965 standard), X-ray inspection (ASTM E1444), fluorescence penetrant testing (defect detection rate ≥ 99.9%). High end field certification ISO 13485 (medical devices), supporting delivery in sensitive fields such as military industry and implants.

Medical titanium materials undergo electrolytic polishing (in accordance with ASTM F86 standard) and passivation treatment (salt spray test ≥ 1000 hours) to meet the surface cleanliness requirements of human implants. Aerospace field: engine compressor blades (weight error ≤ 0.1g), spacecraft lightweight brackets, etc. In the field of marine military industry: deep-sea pressure resistant shells, shipborne radar brackets, etc.

3、 Quick response system: 24-hour sample express channel (first sample delivered within 72 hours), full process delivery of small batch orders within 10 days, 50% faster than the industry average. Cost substitution solution: Provide titanium aluminum composite structure design (reducing weight by 20%), additive manufacturing lightweight topology optimization, and overall cost reduction of 15-25%.

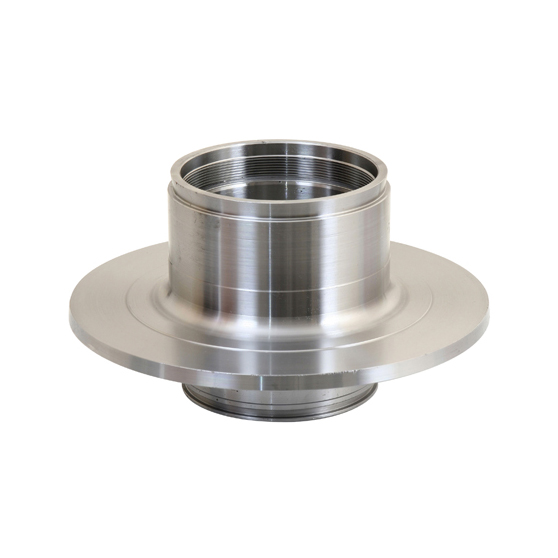

Titanium alloy TC4 parts

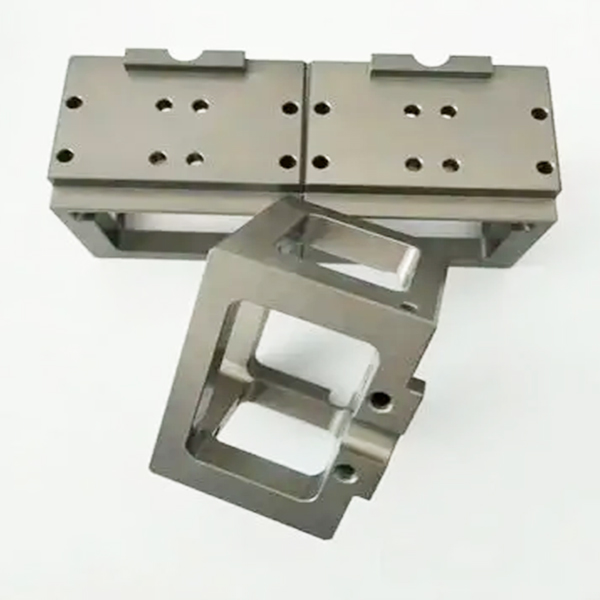

Titanium alloy TC5 parts

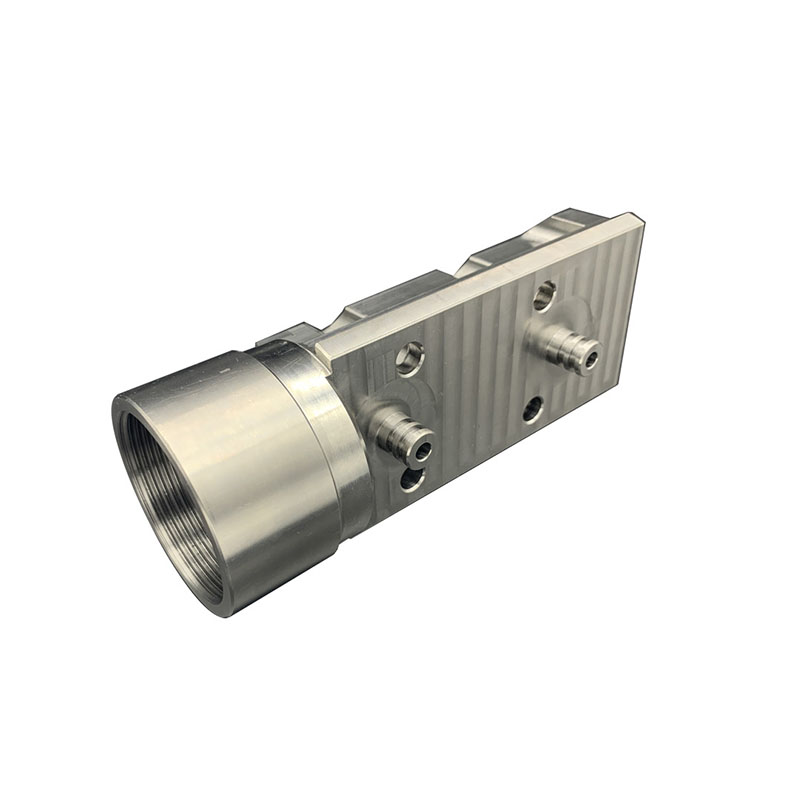

machining titanium

titanium cnc machining

cnc titanium

titanium machining services

cnc milling titanium

machining titanium lathe

Titanium alloy TA2 parts

Titanium alloy CNC machining

CNC titanium alloy

Titanium alloy processing

cnc titanium parts

machining of titanium

titanium precision machining

Titanium parts processing

Do you need a project quotation? Contact us now via phone, email, or contact form